|

|

||

| Offshore Fleet | ||||||||||||

| Jackup rig | ||||||||||||

Offshore exploration and development wells are often drilled from mobile offshore drilling units (MODUs, pronounced "moe-dooz"). Depending on the water depth and remoteness of the location, these "rigs" may be jack-ups (up to 400 feet of water), or semisubmersibles, or drillships (up to 12,000 feet of water). Jack-ups are bottom-supported units; semisubmersibles and drillships are floating units ("floaters"). In terms of numbers, jack-up rigs drill most offshore wells. Semisubmersibles run a distant second, and drillships come in third, though most of the major new discoveries today are being made by the floaters in deep and ultra-deep water. Oil companies ("operators") select rigs that are specifically suited for a particular job, because each rig and each well has its own specifications and the rig must be matched to the well.

Maersk Giant, image: Maersk Drilling Jack-up rigs are so named because they are self-elevating-with three or four movable legs that can be extended ("jacked") above or below the drilling deck, or hull. Jack-ups are towed to the drill site with the hull, which is actually a water-tight barge that floats on the water's surface, lowered to the water level, and the legs extended above the hull. When the rig reaches the drill site, the crew jacks the legs downward through the water and into the sea floor (or onto the sea floor with mat supported jack-ups). This anchors the rig and holds the drilling deck well above the waves. Jack-up rigs drill through slots in their hull, or have the ability to extend ("cantilever") the drilling package out over the side of the hull. A cantilevered rig is very useful for drilling a series of wells over an established production platform, because the rig can move beside the platform and then extend the drilling package over the top of the platform to drill a sequence of development wells. Usually, jack-ups are towed by several towboats to their drilling location. When distances are long, they are placed on heavy-lift vessels for transport. The jack-up's deck provides space for drilling equipment, supplies, and living quarters. Helicopters and supply boats transport workers, equipment, and supplies from shore to rig. One of two types of bottom-supported MODUs (the other being the much less popular submersible rig), jackup rigs rest on the sea floor rather than float. The premise of a jackup rig is that it is self-elevating; here, the legs are stationed on ocean floor and the drilling equipment is jacked up above the water's surface. Providing a very stable drilling environment, in comparison to other types of offshore drilling rigs, jackups can drill in waters up to 350 feet deep. Once drilling is required in waters that are deeper than the capabilities of a jackup, semisubmersibles and drillships become a more logical choice for exploration and development operations. When their legs are not deployed, jackups float, which makes these types of MODUs quite easily transported from one drilling location to another. While some are capable of self-propulsion and do not need an outside source for movement, most jackups are transported via tug boats or submersible barges. While towing is easily performed, barges are the transportation of choice when the jackup needs to be moved quickly or over a longer distance.

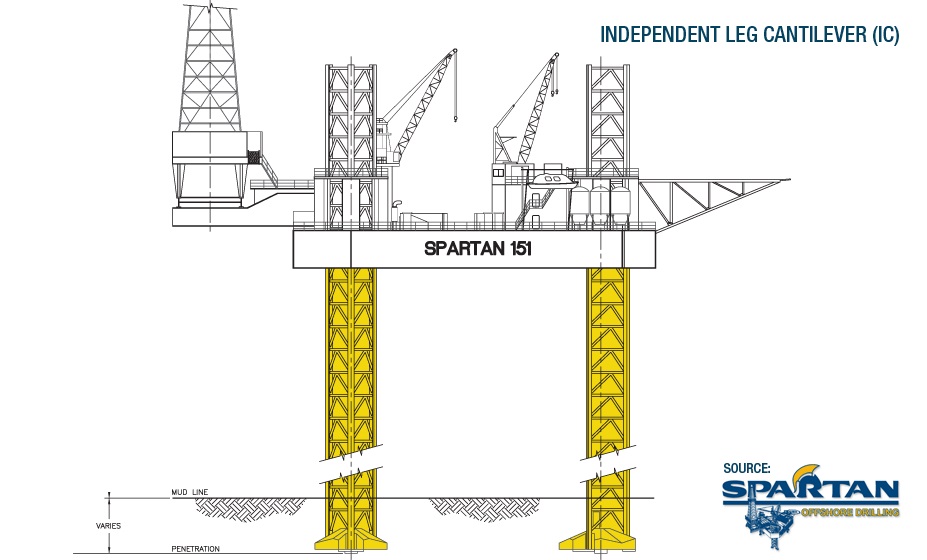

Whether a jackup design involves three or four legs, there are two main types of legs that are used on jackups. The first incorporatesopen-truss legs into the design that resemble electrical towers. Open-truss legs are made of tubular steel sections that are crisscrossed, making them strong, but lightweight. Jackups can also have columnar legs made of huge steel tubes. While columnar legs are less expensive than open-truss legs to fabricate, they are less stable and cannot adapt to stresses in the water as well as open-truss legs. For this reason, columnar-legged jackups are not used in waters that measure more than 250 feet deep. In addition to their legs, jackups are supported by two different systems of stabilization. Jackup legs are supported on the sea floor via either mats or spud cans.

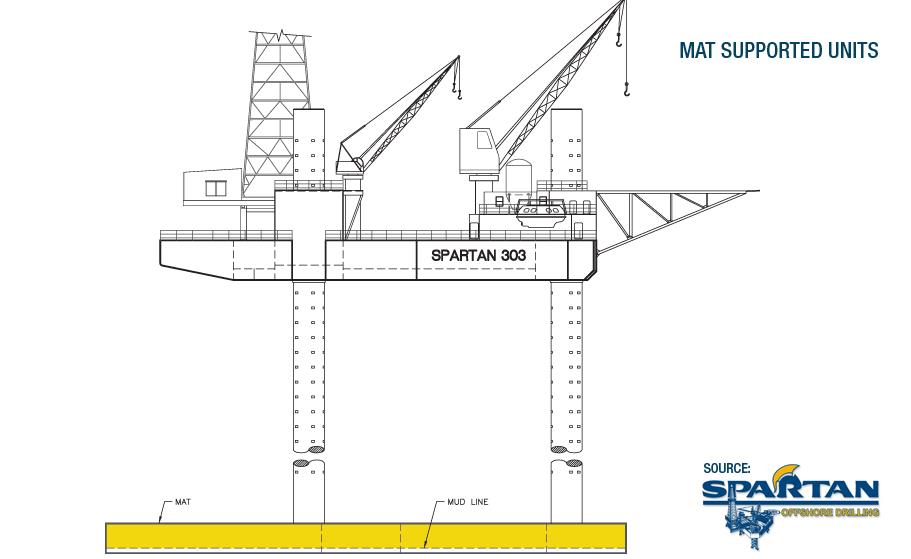

A more logical choice for drilling environments that have soft floors, mat-supported jackups distribute the weight of the rig across the ocean's bottom, like a snow shoe. Usually shaped like an "A," mat supports are connected to the bottom of each leg of the jackup, ensuring that the rig does not punch-through the ocean's bottom. Usually used onindependent-leggedjackups, spud cans are cylindrically shaped steel shoes with pointed ends, similar to a cleat. Spud cans are attached to the bottom of each leg, and the spike in the can is driven into the ocean floor, adding stability to the rig during operations.

Additionally, there are two types of elevating devices. Once the jackup is on location, the legs are lowered to the ocean's floor and the rig hull and drilling equipment is elevated well above the water's surface and away from any potential waves. The first type of elevating device uses hydraulic cylinders equipped with moving and stationary pins. These cylinders extend and retract to climb up and down the legs of the jackup. The other type of elevating device employs a rack and two pinion gears that are turned to move the legs up and down.

|

||||||||||||

| « Back to all Offshore Fleet | ||||||||||||

|

|

|

|

|

||||||||||||